Water is one of the most precious commodities on our planet. It is our job as water quality management experts to make that water cleaner, better and more useful while saving costs, preserving energy and easing the labor burden. One of the most frequently overlooked tools in a water specialist’s arsenal is oxygen and more specifically the triatomic allotrope that we call ozone.

History and chemistry

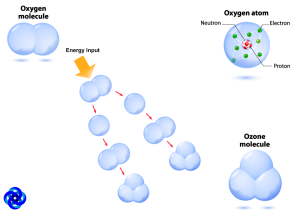

Ozone consists of three oxygen molecules and has a very short half-life compared to its diatomic cousin that we all breathe: O2. While mankind has recognized the odor of ozone as the smell of lightning in a rain storm since the dawn of time and Dutch chemist Martinus van Marum generated ozone electrically in 1785, ozone was only isolated, recognized and named as an allotrope of oxygen in the 19th century by Christian Friedrich Schönbein and Jacques-Louis Soret. Ozone’s inherent instability is what makes it so very attractive to a water dealer; it oxidizes everything it touches in water for about a half an hour at room temperature and then fades away into safe, stable O2.

Generating ozone

In nature, ozone is produced through solar radiation and lightning strikes. Synthetic ozone generation can be through corona discharge, UV radiation, electrolysis and radiochemical reactions. Each method uses an external energy input to break up stable O2 molecular bonds that allow the formation of ozone – O3. We shall focus on the two most common methods:

Corona (cold spark) discharge is by far the most common form of commercial/industrial ozone generation in our industry, since it is capable of greater ozone output per unit of electrical input. Corona discharge ozone production uses a high-voltage power source, anode, cathode and a suitable dielectric separator. Oxygen-rich air passes between the electrodes over a dielectric, creating an electric field (corona), which allows for the formation of ozone. The voltage and frequency of the electrical input affect ozone production. Voltages from 10–30kV and usually used, at frequencies anywhere from 60Hz to 4kHz. One generally sees increases in production at higher frequencies, but those higher operating frequencies can increase production costs and operational complications. Corona discharge systems are sensitive to the incoming air quality and work best with clean, cold, dry air. When moist air is introduced, nitric acid can develop, which will cause serious performance and maintenance problems. Keep the feed air cool, dry and particulate filtered to 5 micron or less to ensure the very best results.

Ultraviolet light – Ozone is produced by reacting oxygen with UV light in the ~185 nm spectrum. Energy from the ultraviolet light causes dissociation of oxygen molecules and allows for ozone formation. These systems are generally the cheapest technology to deploy, but do require significantly more energy input than corona discharge. One of the touted benefits of UV ozone generation is that little or no air preparation is required. Remember though that ozone output quality is inevitably related to the input air quality, so without giving it clean, highly oxygenated air, the UV-based ozone generator will produce very low concentrations of ozone and still suffer potential moisture-based complications.

Potential applications for ozone technology

Water disinfection. Ozone is a viable alternative to chlorine. Ozone kills faster than chlorine, without creating the same volatile organic byproducts of disinfection. Ozone is best used as an adjunct to chlorine, thereby significantly reducing the amount of chlorine used while still retaining a residual active disinfectant in the water well beyond ozone’s half-life.

CIP systems. All food, beverage and vitamin production facilities have an established need for non-toxic clean-in-place (CIP) solutions. Ozone dramatically simplifies CIP by lowering heating energy costs, reducing the amount of cleaning chemicals required and eliminating disinfectant chemical residuals.

Cooling towers. Airborne mold, fungus and bacteria are significant concerns to building operators maintaining a cooling tower. These contaminants foul heat exchangers, contribute to microbially induced corrosion and of course, pose significant risks to human respiratory health. Properly executed ozone treatment effectively eliminates living organisms and other organic challenges from the recirculating water stream, which aids in minimizing hard water adhesions by eliminating the biomass.

Waterfalls, fountains and other water features. The trend towards decorative indoor humidification and ‘living walls’ has resulted in a massive increase in atmospheric water exposure in homes and buildings. Water features can become major indoor air quality (IAQ) liabilities if bacterial contamination is not properly controlled. While many water-wall manufacturers design UV disinfection into their recirculation chambers, field-experience shows that the most effective method for keeping heterotrophic bacteria under control in this kind of application is simple ozone injection. Ozone also aids in controlling odors from organic decomposition and minimizing the propagation of mold and fungus.

Wastewater remediation. Wastewater is increasingly becoming the focus of regulatory scrutiny, whether from local sewer districts or federal authorities. This is a source of significant revenue to regulatory bodies and every plant operator must be certain that BOD, COD and TSS levels are well within compliance. Ozone and AOP are invaluable tools in attaining these goals economically and reliably.

Iron, manganese and hydrogen sulfide. The bane of rural water users world-wide, iron and manganese cause color and staining issues in water that affect residential, commercial and industrial users. Ozone effectively oxidizes ferrous iron into a ferric form that is easily filtered by multimedia treatment. It has the same effect on manganese contamination. As a side benefit, ozone is highly effective in destroying iron-reducing bacteria and other iron-related bacteria that contribute to undesirable tastes, odors and aesthetics in water. Hydrogen sulfide (H2S) and sulfate-related bacteria are responsible for undesirable odors and corrosive conditions in well water around the world. Ozone can be effectively employed to kill bacteria, neutralize odors and oxidize hydrogen sulfide into a filterable precipitate.

Pools, spas and aquatic ecosystems. Ozone is an effective technology for addressing organics, controlling algae and killing bacteria in aquatic applications. Ozone concentrations as low as 0.5 mg/L have been shown to be quite effective in killing waterborne pathogens, like Pseudomonas and Legionella, in a significantly shorter time than with chlorine or bromine. In swimming pools, the most exciting benefit of ozone is the reduction of chlorine usage and of course, the associated chlorination byproducts such as THMs and chloramines.

Advanced oxidation processes (AOPs)

AOP harnesses the power of hydroxyl radicals and has matured as a technology to the point of widespread adoption. AOP allows the savvy water specialist to address amino acids, aromatics, herbicides, pesticides, hydrocarbons, organics and VOCs in wastewater. Properly executed AOP effectively destroys contaminants by rendering them down to their constituent elements. Ozone can be a solid backbone of an effective AOP installation when installed with UV radiators and an appropriate catalyst. AOP requires a significant level of knowledge and understanding of water chemistry; consult with your vendor or industry consultant carefully to ensure that you are deploying a viable solution. I am a firm believer in deploying in-situ pilot plants to gather sufficient operational data before investing in the capital expense of an operational AOP system.

Calculating minimum ozone demand

Determining the ozone demand of the water requires an accurate water analysis and an understanding of the amount of ozone required to react with certain contaminants. All experts have their opinions; the data below is from the criteria that I use when sizing systems. Consult with your expert and decide what you both are comfortable with before proceeding.

|

Contaminant |

Minimum ozone dosage per mg/L of contaminant | |

| Iron (Fe) | 0.43 mg/L | |

| Manganese (Mn) | 0.87 mg/L | |

| Hydrogen sulfide (H2S) | 3.00 mg/L | |

| Tannins | 1.6 mg/L | |

| Nitrite | 2.0 mg/L | |

| Phenol | 2.1 mg/L | |

| Total organic carbon (TOC) | 4.0 mg/L | |

| Biochemical oxygen demand (BOD) | 2.0 mg/L | |

| Chemical oxygen demand (COD) | 2.0 mg/L | |

Disinfection applications require a minimum ozone dosage of 0.5mg/L in addition to any other established ozone demand.

Calculating minimum ozone generator production rate: Grams of ozone per hour = water flow (liters/hour) X ozone demand.

- Calculate the flowrateto be treated in L/hr.

Convert US customary units to metric as follows: (GPM x 60) x 3.785

For example: 10 gpm x 60 = 600 gallons per hour

600 gph x 3.785 =2,271 liters per hour

- Multiply minimum ozone demand by L/hrto calculate mg/hr minimum production rate.

- Divide by 1,000to determine the minimum grams per hour that the ozone generator needs to produce. Complicating factors like chelates, organic complexes, transfer efficiency and even water temperature fluctuations will interfere with textbook ozone demand calculations, so plan for an appropriate reserve capacity of 20-30 percent beyond minimum to allow for flexibility in treatment. It’s much better to throttle down your ozone production rate than to wish that you had more to work with.

Do not overlook safe handling procedures

Ozone is an extremely powerful and unstable oxidizer that can be dangerous to humans and other animals. Concentrated ozone is pungent like chlorine and not surprisingly, they both act similarly against living organisms. Airborne ozone can cause:

- Aggravation of asthma

- Throat irritation and cough

- Chest pain

- Shortness of breath

- Susceptibility to pulmonary infections

- Damage to eyes and mucosal membranes

- Damage to skin

- Decreases in lung function

The US Occupational Safety and Health Administration (OSHA) guidelines for O3 in the workplace are based on time-weighted averages. Ozone levels should not exceed 0.1 ppm for each eight-hour-per-day period of exposure doing light work. A good rule of thumb is that if you can smell ozone, the concentrations are high enough that you should immediately evacuate the area and properly ventilate before returning to work. Think of ozone as a dangerous animal. When handled carefully and with respect, you’re going to be safe; if you let it out of its cage or treat it without the appropriate respect and caution, it will inevitably hurt you.

Best practices

When designing an ozone installation, always make the safety of installers and users your goal.

Ozone generators should be kept cool, with an ambient temperature below 80°F/26°C. Humidity should also be kept well below one percent to prevent the formation of nitric acid within the ozone generation chamber(s) and distribution piping. After calculating the ozone demand for the application, choose a quality ozone generator from a reputable vendor. Consult with your vendor on whether you will use a liquid oxygen feed, oxygen concentrator, or ambient air feed. Then discuss the ambient operating temperature and relative humidity and plan for appropriate cooling and dehumidification as necessary.

Select a method for injecting ozone into the water stream. Venturi injectors are simple and relatively inexpensive, but there are also certain applications where an ozone concentration pump (compressor) is appropriate. In some cases, you might decide to treat the water atmospherically in a holding tank or pond using an ozone diffuser. The next step is to calculate the retention volume required to maximize contact time. This is easy, simply multiply the time required by the operating flowrate. If you’re running at 10 gpm and require six minutes of contact time, you’ll need a total mixing/retention tank volume of at least 60 gallons (227 liters).

Monitoring of ozone residuals in the downstream water is wise when working with fluctuating contaminant levels. Where budget permits, automated process monitors can be installed that have data logging capabilities as well as analog voltage outputs to signal other monitoring and automation components. After sizing and selecting system components, safety measures and monitoring, the appropriate consideration should be given to operating procedures, minimum maintenance requirements and operator training. When I consult with dealers or end-users on malfunctioning ozone systems, the most common problem that I see is poor maintenance and upkeep. Ozone systems, like all water treatment technologies do require periodic maintenance, so plan appropriately.

Things to remember:

- Safety first

- Ozone generators work best with cool, dry air (<-60F dew point, which is a relative humidity of <1%).

- More feed oxygen concentration = greater discharge ozone concentration

- Ozone dissolves better in cooler water.

- Ozone is effective for longer in cooler water.

- One ozone feed check valve is good, two are better.

- Ozone destroys rubber seals and other organoplastic materials.

- Ozone has a low vapor pressure.

- Ozone clings to rough surfaces.

- Ozone reacts differently at various pH levels.

- While ozone costs more upfront, it is often cheaper to maintain and operate than other oxidizers.

Conclusion

Ozone is a powerful tool that can help you make better water for your clients. You’d be wise to learn more about this useful tool by reading trade journals like this one, taking classes from the various manufacturers and dealer networks and of course, using WQA’s Modular Education Program (MEP).

Glossary

Allotrope. An alternate structural form of an element that can exhibit dramatically different properties from the other forms.

Biochemical oxygen demand (BOD). A BOD test is a way to measure how much oxygen is being consumed by microbes in a water sample. The more contaminants in the wastewater, the more oxygen is needed to sustain life. High BOD numbers indicate high concentration of contaminants in the wastewater that the microbes have eaten. Oxygen content is measured when the test starts and again at the end of five days. The difference in the oxygen content between the first day and last day is used to calculate the BOD of the water.

Hertz (Hz). Hertz is a unit of frequency of one cycle per second. Named after Heinrich Hertz, it replaces the earlier term of cycle per second (cps). The kilohertz, abbreviated kHz or KHz, is a unit of alternating current (AC) or electromagnetic wave frequency equal to one thousand hertz (1,000 Hz).

Oxidation. The loss of an electron. Substances that can cause other things to donate their electrons are known as oxidizers or oxidants.

Trihalomethanes (THMs). Chemical compounds in which three of the four hydrogen atoms of methane (CH4) are replaced by halogen atoms. THMs are formed as a byproduct when chlorine is used to disinfect water. The THMs produced have been associated through epidemiological studies with some adverse health effects and many are considered to be carcinogenic.

Total suspended solids (TSS). A measure of suspended solids in a water sample. A measured amount of the water is passed through a weighing disc that captures particulate >1 micron. The amount of particulate captured in the disc is weighed after dehydration and then extrapolated to determine an indication of total suspended solids in the sampled water.

Venturi injector. The Venturi effect (named for the 18th century Italian physicist), as applied to fluid eduction, is a phenomenon whereby the rapid reduction of water pressure in one direction allows for the creation of a vacuum in another. This is the phenomenon whereby most modern water softeners draw brine from the brine tank during regeneration.