Smart business owners and managers understand that innovation is essential to business longevity and prosperity. In a successful water treatment service company, it is imperative to understand, deploy and maintain cutting-edge technologies to help provide customers with better water.

As we continue to see more misguided attempts at softener bans and a continued emphasis on minimizing our net environmental impact, the need for more environmentally friendly water quality improvement technologies becomes glaringly apparent. Progressive manufacturers have deployed technologies like fractional brining, twin-tank sensor technologies and other innovations that dramatically reduce salt consumption for water softening use to effectively address these concerns. While our industry continues to document and prove that salt-based ion exchange softening has a positive environmental impact, our customers are clamoring progressively louder for salt-free solutions to their hard water problems.

Salt-free softening has been the ’holy grail’ of the water treatment industry for a number of years. The performance criteria for salt-free softening systems are twofold:

- The device must be capable of delivering an effluent hardness level <= 1gpg (17.4 ppm).

- The device must not use any salt (sodium or potassium) in the process of softening the water or when cleaning/regenerating itself.

Currently, the only practical and effective salt-free softening technologies are membrane separations and the electrolytic removal of hardness ions. The purpose of this article is to briefly introduce certain electrolysis technologies and their potential for use in residential applications.

Benefits of EDI

There are many benefits to using an electrolysis technology over traditional ion exchange:

- Simple and consistent operation

- No regeneration chemicals

- Few or no moving parts

- Uniform operation at varying water pressures and water chemistries

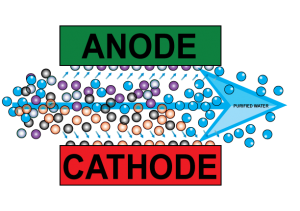

Electrodeionization (EDI) is a simply brilliant concept: Water containing ionic impurities is passed through a deionization chamber that contains anionic resin, cationic resin and two electrodes, each separated by semi-permeable membranes of alternating polarity. The electrodes attract ions unidirectionally through resins and out of the feed water stream, which then becomes purified. A concentrated stream of removed ions and water is continuously discharged to drain. Since the electrodes are continuously energized, electrolysis liberates hydrogen and hydroxyl ions from the purified water, donating regenerative ions to the resins and enabling the process to continue indefinitely.

EDI has been used successfully for many years as an effective alternative to acid/alkali deionization. IT is particularly sensitive to sediment, silica, chlorine and calcium carbonate hardness, all of which will interfere with the device’s ability to clean water. Traditional EDI technology is not therefore, generally suitable for use as a softening device. EDI is the technological springboard that has allowed inventors to develop other more appropriate technologies for residential salt-free softening.

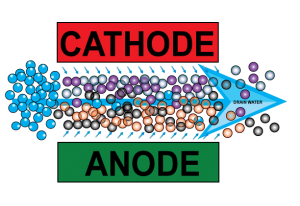

Capacitive deionization (CDI) employs electrodes separated by the raw water stream. When the electrodes are charged with DC electricity, they attract inorganic ions from the water and hold onto them with varying degrees of effectiveness, depending on their molecular weight and ionic charge. The electrodes eventually reach their maximum capacity and then need to be cleaned by discharging and reversing electrical polarity. Reversing polarity causes the electrodes to actively repel the ions that they were previously attracted to. This intermittent or ‘batch’ regeneration saves water and energy while reducing capital outlay on equipment materials, as well as allowing for a smaller installation footprint. CDI typically recovers at least 80 percent of the water that it treats, compared to 50-70 percent for most membrane separation offerings.

|

|

| CDI in Service | CDI in Regeneration |

The following should be considered when deploying CDI technology:

While feed water conductivity equivalents (FCE) do not usually need to be calculated for residential applications, influent water should still be tested for hardness, iron, silica, sulfates, conductivity, and alkalinity. Test data must be compared to manufacturer’s specifications to ensure compatibility and appropriate pretreatment.

- Low TDS output water can potentially create corrosion issues, so the product water needs to be TDS-controlled to ensure an output water quality that is compatible with household appliances, faucets and fixtures while still being soft or at a level of calcium hardness that is acceptable to the end-user.

- Any technology that employs electrolysis will produce gases as a byproduct, most notably oxygen, hydrogen and chlorine. These gases need to be safely vented or neutralized.

- A reliable, unswitched electrical supply must be located conveniently to meet the electrical requirements of the appliance. Unlike a traditional salt softener, CDI systems do not soften during power failures, so an uninterruptable power supply (UPS) might be considered in applications requiring a continuous supply of softened water.

- A code-compliant drain must be provided to allow discharge of drain water during a system cleaning cycle.

- A needs analysis should be performed to understand the flow demand in the home. Based on flow demand, the savvy dealer can deploy multiple processors or even utilize retention or blending tanks to provide the required amount of water.

While CDI is a promising technology for water softening, it is not economically viable as an outright replacement for traditional salt-based softeners yet. As large manufacturers embrace the technology and manufacturing processes improve, economics of scale will drive prices downward. As solar-energy production and hydrogen fuel cell technologies become more efficient and cost-effective, it is not inconceivable that water dealers could be installing alternative-energy-powered, electrically regenerated ion exchange systems for their customers within the next 10 years. The concept of a net-zero environmental impact softener now becomes far more realistic than ever before.

Glossary:

Electrolysis – Using a direct electric current (DC) to drive an otherwise non-spontaneous chemical reaction.

Mesoporous carbon – Carbon containing pores with diameters between 2 and 50 nm.