It is common practice in many areas to refrain from softening all water inside a home, specifically isolating fixtures like kitchen cold-water, bar- and vegetable-prep sinks, etc… There are a number of reasons to do this, but I’d like to address the wrong reasons first:

- Soft water has salt in it

- Soft water doesn’t have healthful calcium in it

- Soft water is corrosive

- Soft water causes heart attacks

The preceding fallacies are the most commonly cited reasons that I hear for plumbers and other water quality improvement contractors bypassing the kitchen cold-water sink from softened water. These fallacies have been debunked in WC&P and in numerous other scholarly publications, but it will take many hours of training for the logic to penetrate for some. Many progressive plumbers and water system dealers are now plumbing all fixtures in the home with softened/conditioned/filtered water and then adding EDI or RO to specific points of use to help clients who prefer the taste of purified water, or seek the additional health benefits from removing as much from the water as possible before adding aquaceuticals or drinking and cooking with the plain purified water. While progressive dealers treat the water systematically, there are still countless other misinformed and/or stubborn installers who insist on plumbing hard water to the kitchen cold-water sink and sometimes, to other cold water fixtures. This common installation practice creates a potential problem for the entire installation…the dreaded crossover.

The problem

Crossovers are situations where two sources of water mix or blend in an unintended/unplanned manner. The most typical crossover is when hard water at the kitchen sink crosses over through the faucet mixing valve/cartridge, then makes it way backwards to the water heater where it can contaminate the softened hot water with undesirable hardness minerals, chlorine, metals and possibly other contaminants. Crossovers can be difficult for service technicians to test for, especially if they don’t understand a truly systematic approach to troubleshooting.

Crossovers blending hard and soft water in the home can occur continuously or intermittently and when they do occur, they are irritating to the homeowner as well as repair technicians. An example of a typical continuous crossover condition is when no matter how hard the technician tries, the softener seems incapable of reducing water hardness in the home by more than about 80 percent. An intermittent crossover is where the homeowner reports that the water sometimes ‘feels hard’ but is usually soft when the repair technician visits the home.

When suspecting a crossover, it is a good idea to gather and document the following data:

- Influent (untreated) hardness

- Effluent (treated) hardness

- Water pressure

An example of this situation would be:

- Influent hardness 20 gpg

- Effluent hardness 4 gpg

- Water pressure 75 psi

Assuming that the softener has already been tested and verified to be mechanically functional and the distributor pilot O-ring integrity has been confirmed, one can assume that a hard water crossover could be a problem here. The key to identifying and rectifying crossovers is to be methodical. Take the time to work systematically, and document your work as you go.

The most common method for physically diagnosing a crossover is to simply shut the soft water loop. This can be accomplished by using a three-way, ball-valve bypass or with specially ported two-handle bypass valves commonly found on professional-grade softeners and conditioners. Shutting off the soft water loop prevents water from flowing through the softener to the attached plumbing. It then becomes relatively easy to determine which fixtures are plumbed soft and whether a potential hard-water crossover exists. Once the softened loop has been shut down, the technician simply opens all the water-using fixtures in the building, from the lowest to the highest point, and waits an appropriate period of time for the fixtures to drain down (five minutes for every 1,000 feet [304.8 meters] of livable floor space is a commonly used figure). Once the fixtures have had an opportunity to drain, all softened fixtures should have absolutely no flow at all. If the kitchen cold (or any other faucet/fixture) is running at full speed at this point, then it is clearly evident that it is ‘plumbed hard’.

By simply closing the hard feed water stop to the fixture, one can determine if the crossover is occurring there. Let’s say that the kitchen cold water is running full flow and the technician turns off the angle-stop under the counter…by turning off the angle-stop, the hard-water feed is unable to pass through the faucet. The technician can now turn the soft-water loop back on and test water quality, after rinsing for an appropriate period of time. If the water is suddenly soft, this is proof positive that a crossover condition has been occurring in the home.

Fixing crossover is relatively easy, by taking a pro-active approach during installation of the water treatment system. Installing a simple check valve on the hot water side of the afflicted fixture will permanently prevent hard water from moving backwards to the water heater or from contaminating other fixtures.

Compounding the problem

In certain extreme cases, hard-water crossover doesn’t just inconvenience the homeowner by pushing hard water backwards to the water heater and the installer trying to resolve the issue. Sometimes the problem can be much worse. During regeneration, the water softener becomes the path of least resistance for hard water crossing back through the water heater. This can introduce piping hot water back to the softener during backwash and potentially damage the polyethylene distributor and riser assembly, resulting in catastrophic resin release into the building. The solution is to install a spring check valve on the outlet of the water softener.

Best Practices

This discussion about crossovers reminds one that it is always a good idea to use industry best practices when installing water treatment equipment. Yes, it will cost more to do things right, but it certainly results in fewer call backs and happier customers.

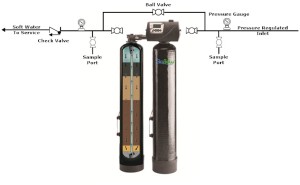

Current industry best practices include installation of the following:

- Inlet water pressure regulator

- Inlet pressure gauge

- Inlet sample port

- Bypass that allows for proper soft-loop isolation

- Outlet sample port

- Outlet pressure gauge

- Outlet check valve

Do the very best job that you can, and your customers will appreciate it.

This is an excellent article and I think it may explain a strange issue I’ve been having in my home for the last week or so. It’s actually two issues which I now believe, after reading your article, may be linked.

Issue 1: My kitchen sink is plumbed hard on cold. When I turn on the hot water at the sink, ice cold water comes out for 2 seconds or so, even if I’ve just shut off the hot water in the previous 5 seconds. It’s consistent and repeatable.

Issue 2: Hot water is backing up into my softener (I have no check valve installed).

My house is plumbed for a hot water recirculating circuit which is in operation. From your article, it sounds like I may have a crossover condition occurring at the kitchen sink causing the water to push back toward the softener. Does this sound like a plausible explanation to you? Do the symptoms fit?

Thanks for your time.

Hi Dustin, yes your symptoms certainly do fit, and should be properly addressed as soon as possible.

If you haven’t already, you should experiment with shutting the stop at the kitchen cold and see if the shot of cold water before it goes hot suddenly stops. This would confirm our suspicions beyond doubt.

Where is your recirc return located? Is it at the inlet to the water heater, or somewhere else?

Hi,

Thanks for your quick reply. Yes, shutting off the cold water at the stop prevents the immediate burst of cold. However, I haven’t been able to keep it shut off long enough to determine if it prevents the hot water backup into the softener, or not.

The recirculation return is located at the bottom of the water heater. The recirc pump’s check valve is stuck open (but has been for at least a year). I’m planning to replace it soon (part on the way), but can’t imagine how that could be causing my problem, especially since the issue seems to occur more consistently when the recirculation pump is running. Perhaps the crossover condition has allowed hard water to back up into the recirc circuit, and that’s part of the reason my recirc check valve failed so early in its life (the house is less than 5 years old).

One thing I forgot to mention is that my faucet is one of those Delta Touch2O faucets, so the valve is technically open all of the time (unless I manually close it). The hot and cold feeds run to the mixing valve, then back out to a solenoid, before coming out of the faucet. The touch feature opens and closes the solenoid, but there is nothing stopping the hot and cold lines mixing or “crossing over” when the solenoid is closed, if the mixing valve is open.

I’m starting to think that this crossover condition has existed since the house was built, but that it’s only become obvious in the last week or so. The weather just turned quite cold here in Albuquerque (cold for us, anyway), and I’m wondering if the greater temperature difference between the cold and hot water lines has exacerbated the problem. This might also explain why the water in my house never felt as soft as it should.

In any case, it would seem my best bet would be to install the check valve at the hot water line under the sink, as you outlined in your article. The problem is, I’m not sure where to buy a check valve for this application. The local orange hardware store has nothing to suit this application. Haven’t checked at the blue store, yet.

Thanks again for your help!

Hi Greg,

Well, that was the problem. The cold, hard water was crossing over into the hot line at the kitchen sink. The problem was exacerbated by the fact that the Delta Touch2O faucet’s mixing valve can stay open even when the water is off (closed solenoid). When the faucet was first installed, check valves were installed as well (on both cold and hot lines), as is required by the manufacturer to prevent just such a condition. It had been 4 1/2 years since I installed this faucet, and I simply had forgotten that there were check valves in the system. Regardless, the check valve on the hot line has failed. Delta is sending me two new ones. For the meantime, I have disabled the solenoid and am using the mixing valve exclusively to control water flow. The issue has completely resolved.

Thanks for your excellent article. It was instrumental in helping me diagnose this issue.

-Dustin

You did a perfect diagnosis. I’m sure your experience will help others suffering from the same issue – well done!