By Mike Mecca, and Greg Reyneke – As published in Water Quality Products Magazine, May 2nd 2013

Stated simply, hard water is water that is hard to lather, and soft water isn’t. A more technically accurate definition of soft water describes the physical removal (to less than one grain per gallon in most cases) of calcium and magnesium salts. However if you cheat and go to the end of this article, future generation’s definition of Soft water might read –Less than 4 GPG as defined by the US Geological Survey!!

The salt-based softening market blossomed after World War II and is the gold standard by which all other technologies are judged. The first residential water softeners were portable exchange tanks. They were simple, foolproof and gave you soft water – nothing more nothing less, brine efficiencies hadn’t yet entered our dictionary.

The salt-based softening market blossomed after World War II and is the gold standard by which all other technologies are judged. The first residential water softeners were portable exchange tanks. They were simple, foolproof and gave you soft water – nothing more nothing less, brine efficiencies hadn’t yet entered our dictionary.

Progressive water dealers soon realized that the portable exchange model was seriously flawed and they pushed manufacturers to develop ’regenerate in place’ systems that they could sell to their customers. A removable lid was incorporated into the tank, whereby homeowners could load their own salt regenerant dosage into the system and then manipulate a series of gate-valves in a specific sequence to regenerate the system and rinse away the byproducts of regeneration. This was more convenient for the dealer, but not necessarily for the homeowner, since they were periodically opening a pressurized vessel and exposing their family to the inevitable bacterial and leak liabilities.

Time became an increasingly more valuable commodity to homeowners and plant operators, so manufacturers introduced the “automatic” water softener, a system that used on onboard mechanical timer and automated regeneration component assemblies. This simple technology was certainly revolutionary in its day, saving people time and bringing the industry closer to the ultimate goal of ensuring an uninterrupted supply of soft water to every home and business in the world. These Automatic systems were so simple, reliable and easy to operate that many people still buy them nowadays in areas where they haven’t been banned yet.

Environmental consciousness awoke in the United States during the 1970’s, ushering in an era of increased awareness of pollution-control and resource conservation issues. The consumer market demanded a more efficient solution than merely guessing on which day of the week to regenerate the softener. Residential softener manufacturers began marketing ’upflow’ (counter-current) regenerated softeners that induced brine into the softening tank opposite the service flow, allowing for a more complete cleaning cycle, as well as squeezing further efficiency out of the synthetic gels resins. Upflow regeneration technology (when properly deployed) provided significant salt-savings as well as improved water quality, but the market still demanded more…

Mechanically metered water softeners were introduced to allow dealers to control water softeners regeneration frequency based on consumption and not just the amount of time that had passed. The system was then able to monitor water consumption and clean on demand, saving salt, water, time and money. As with all analog systems, the mechanical meter contained numerous gears, which made them complex to service and increased the likelihood of mechanical failure.

Cost-effective microcontrollers and hall-effect sensors were introduced to the soft-water industry in the 1980’s. This allowed one-piece flow meters and improved control and flexibility, especially over reserve capacities. Reserve capacity is the minimum amount of water available during a 24-hours period, since the industry decided that 2 a.m. was a good time for regeneration since most people would be asleep and not using the hard water that was bypasses when a single-tank system regenerated.

Formulas for the perfect reserve, were developed and are still the subject of spirited debate amongst soft water technicians and dealers. Innovative manufacturers introduced algorithmic advances, like adaptive and floating reserves, that adjusted over time, based on the measured average daily water consumption in the home, eliminating much of the guesswork involved with standard calculations. Proportional, variable, and fractional brining software further enhanced single-tank softening efficiency; salt dosages could be precisely calculated to use only the exact amount of salt required for each regeneration cycle. Manufacturers and software developers poured massive amounts of time and money into making this softener control software as efficient and user-friendly as possible.

Some manufacturers & dealers don’t even bother selling single tank softeners anymore. They instead promote softeners with two alternating resin tanks, effectively supplying the home with 100 percent soft water, 100 percent of the time. Twin-tank technology is undeniably far more salt efficient and redundant than single-tank technology since reserve capacities are not required, and ion exchange tanks can switch multiple times per day without bypassing to regenerate. Apart from noise or water pressure-loss during regeneration, the time of regeneration is now generally irrelevant. Furthermore, some twin-tank softeners actually clean with softened water to help moving parts last longer as well as protecting the ion exchange media from premature fouling.

Salt-based ion exchange systems soften water very well, and depending on the characteristics of the ion exchange resin used, will also address certain other metallic ions like zinc, iron, copper, zinc, lead and many more. Since municipal water utilities and private wells can’t provide uniformly consistent raw water quality to the home, it is not uncommon to see water hardness levels fluctuate throughout the year. Certain areas in the US will see hardness levels fluctuate from as low as 5 gpg to as much as 80gpg in very short periods of time. Extreme variations like this as well as common seasonal fluctuations make it difficult for a water dealer to provide consistent water quality while attempting to maximize salt & water efficiency. Someone then has to test the water every week and recalibrate the system, or set the capacity to a “best-average” profile, which will either waste salt & water or provide inconsistent water quality.

Many patents exist for sensor-based softeners, where the water softener either senses a change in water quality or resin charge condition. Some sensor designs work well, automatically adjusting the system capacity once a hardness front reaches the sensor, but it is essentially closing the door after the horse has already left the barn when deployed on a single tank system, since it is forced to wait until the designated regeneration time before cleaning itself.

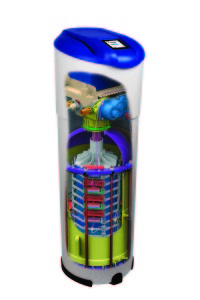

A new & exciting innovation embodies a twin-tank softener with upflow regeneration functionality and dual resin exhaustion sensors in each tank. These epitomize some of the best features in salt-based softening that the industry currently has to offer: redundancy, intelligent sensing and efficient regeneration. After each regeneration, the control creates a new profile of the water conditions for the  upcoming tank to use in its next operational capacity setting.

upcoming tank to use in its next operational capacity setting.

Wouldn’t this ultra-high efficiency be detrimental to the life of the resin? One innovative manufacturer has addressed this concern through smart software that performs a “Deep-Cleaning Cycle”. Deep-Cleaning is a simple concept: Knowing that the resin media slowly loses functional capacity after extended “economy” regenerations, the system will initiate a “Deep-cleaning” cycle after a certain number of regular high efficiency cleanings (the onboard software uses an AI algorithm to determine how often to do this; based on how many gallons have been processed, the age of the system and, of course what the onboard sensors detect about the status of the resin media). During the “Deep-Cleaning” the control will temporarily forego the regular salt and water saving settings to perform a regeneration with a more concentrated brine solution to thoroughly clean the resin. We believe that this configuration will become the new gold standard for performance, consistency and efficiency in the 21st century.

Even though electro-deionization (EDI) and capacitive-deionization (CDI) water conditioners have been available for a number of years, they are now available at an affordable level for home and light-commercial use. Those of us who have designed, manufactured, sold, and installed salt-based systems for a long time sometimes have a hard time understanding these new technologies and they can even be intimidating.

Prominent manufacturers, as well as small boutique-designers, are working feverishly to be first to market with a reliable product that will produce sufficient flow throughput at a price point to be viable for residential deployment. It is not inconceivable that these technologies will provide water as good as or better than salt-based ion exchange through the use of electricity within the next five years. Fundamental to the adoption of these technologies is that they will not bring water to “ZERO SOFT” (<1gpg CaCo3), since they address both cations and anions during the treatment process. If these devices were to remove all the calcium from the water, it would produce water that is potentially corrosive. Since the current alternatives to traditional salt-based water softeners are Physical treatment devices (PWT) that don’t remove hardness, the consumer now has a viable option to significantly reduce the amount of calcium in their water as well as anions that traditional softeners don’t even touch, without adding any sodium or potassium ions to the water.

The paradigm shift required is for the user/dealer to be happy with a small amount of mineral in the water…we believe that this will be a natural and logical decision, since the alternative is no softening at all.

A disappointing observation upon the current state of our industry is that the technologies we have mentioned in this article have been available for a number of years, and very few dealers have the courage to embrace change and adopt technologies that help our industry be more efficient, effective, and environmentally friendly. Well-meaning, yet misguided legislators have banned or attempted to ban traditional salt-based ion exchange softeners because they are concerned about salt and water efficiency.

While we can argue that the benefits of water softening outweigh traditional environmental impacts, this is assuming a weak defensive position. We should rather take the initiative to everything reasonably within our power to make our water quality management solutions more efficient and  effective.

effective.

Mike Mecca is Director of Marketing and Innovation at Performance Water Products

Greg Reyneke is Managing Partner at Red Fox Advisors.

Mike and Greg are advisers to the ProFlow Dealer Network, a Pentair Platinum Partner.

Enjoyed this!

Great article, Greg. Your contributions to the advance of home water treatment have been tremendous. Good work!

Joyce Kiki Takeda liked this on Facebook.

Ronald A Allen liked this on Facebook.

Sharlyn Adams liked this on Facebook.