When you hear the word membrane, most residential dealers think about under counter reverse osmosis (RO) processors. There is so much more to membrane separations than just the filter in the kitchen. The various separation technologies can augment products and services offered to customers.

While the concept of separating ‘things’ from fluids remains unchanged, new technologies are bringing excitement to the membrane separation industry. While there are many exciting possibilities to explore, technologies with an immediate benefit to the residential dealer will be the focus.

Potential applications

Residential water treatment dealers can leverage the latest membrane separation technologies to help clients achieve better water quality. Choosing the correct membrane separation technology requires some basic information:

What is the water quality challenge that I’m facing? Test the influent water carefully for the following contaminants at a bare minimum:

-

-

- Hardness

- TDS

- Total alkalinity

- Chlorine

- Iron

- SDI

- Silica

-

Additional testing might be required, depending on the specific application or on test results on the above contaminants.

Additional questions

What is the water going to be used for?

Depending on the application, you might need additional pre- or post-treatment.

What service flow rate is required?

Membrane separation technologies will significantly reduce the delivered flow of water, so plan accordingly to balance processor speed and storage tank space.

How much raw water pressure and flow are available for processing?

These criteria are frequently overlooked when designing systems and are probably one of the main reasons for system failure. Ensure that you have sufficient flow and pressure available to drive the process. If not, necessary retention and pre-pressurization stages must be integrated into the holistic design.

How much space do I have available?

The slower the system, the more storage space is required to maintain a uniform delivery rate. Don’t discount the value of walls and ceilings when evaluating space available for equipment installation.

What drainage capacity is available onsite?

Most membrane separation installations will be configured in cross-flow or intermittent flow drainage modes. An adequate drain is required to ensure the discharge water can be handled in an environmentally friendly and code-compliant manner.

What electrical supply is available onsite?

Pumps consume significant amounts of electrical energy. Certain pumps might require higher voltages or three-phase supply. Make sure to match the equipment to what is available at the home .

What piping material is to be used for product water distribution?

When integrating whole-house membrane separation technologies that will decrease TDS to less than 150 ppm or lower and pH to 7.3 and below, studiously avoid cupric or ferrous piping components and fittings, or take appropriate measures to balance pH and mitigate low TDS corrosion concerns.

Is the water microbiologically safe?

HPCs and pathogenic bacteria can colonize membrane separation equipment Steps should be taken to minimize contamination during water processing and storage.

Based on the above data, it will be relatively simple to work with OEMs or distributors to size and select the proper technology for the job.

Technologies to explore

Reverse osmosis (RO)

Under counter RO has become commoditized and is now as common as an icemaker filter. A large, untapped market lies in whole-house RO market to properly integrate equipment. 21st century RO technology emphasizes low driving pressure and enhanced water efficiency – factors that are encouraging more dealers to install this technology in customers’ homes. Whole-house RO is most commonly used on high conductivity waters, or when a client is particularly health conscious and wants ‘the very best’ for their home. RO membranes are sensitive to scaling from hardness and silica, so chemical sequestration, ion exchange softening or even scale control technologies should be incorporated as pretreatment to prolong the lifespan of the membrane elements

Nanofiltration (NF)

Nanofiltration is a relatively recent development in the membrane market and is very useful to the water treatment professional who is interested in lowering TDS, clarifying water or orchestrating truly salt-free softening. Nanofiltration elements are usually available in 50 90 percent TDS reduction options, with a generally proportional amount of hardness reduction. Nanofiltration elements address certain high molecular weight aqueous salts as well as suspended and dissolved solids in the 0.001 to 0.1 micron range. Care should be exercised when integrating NF as a salt-free softening system, since the rejected calcium carbonate will scale aggressively throughout the drainage system unless a suitable cleaner is incorporated as part of the overall design. Many dealers are starting to incorporate nanofiltration into their product offerings, especially for homeowners who need to physically remove hardness without dealing with chloride discharge. Nanofiltration is also showing great promise in removing high molecular weight organics from water.

Ultrafiltration (UF)

Ultrafiltration is a coarser form of separation, suitable for separating certain colloids and suspended solids in the 0.1 to 5 micron range. UF is well suited for addressing bacteria, virus and colloids. While UF is a membrane technology, it can also occur in tube or hollow-fiber configurations, which open a number of creative opportunities to serve your client better. I personally prefer hollow-fiber ultrafiltration for residential applications, as it can operate with intermittent forward and back flushing and have a longer element life than spiral-wound technology.

Case studies

Take the time to research membrane separation and learn the nuances of these exciting technologies; it will be very rewarding to customers.

A pet peeve about most articles in trade journals is there aren’t enough real-life examples of how to implement what the author pontificates about. Here are some actual configurations of whole-house residential systems utilizing liquid separation technologies.

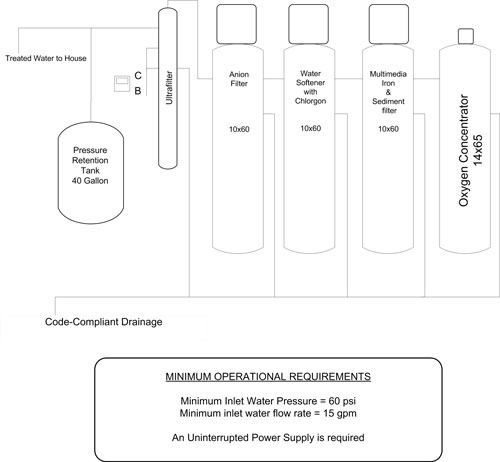

Ultrafiltration case #1

Customer moved into a new home in the city. Although city water was supposed to be completely safe, the customer wanted peace of mind concerning potential bacterial contamination, while also removing hardness, chlorine tastes and odors from the water.

| Before | After | |

| Hardness | 17 gpg | 0 gpg |

| Iron | 0.1 ppm | 0 ppm |

| pH | 7.8 | 7.8 |

| TDS | 180 | 210 |

| Chlorine | 1.3 ppm | 0 ppm |

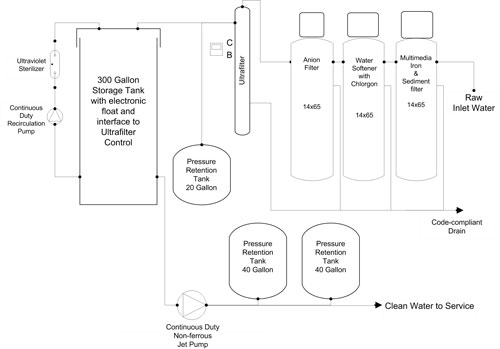

Ultrafiltration case #2

Customer was concerned about hardness, iron, tannins and potential bacterial contamination.

| Before | After | |

| Hardness | 30 gpg | 0 gpg |

| Iron | 3 ppm | 0 ppm |

| pH | 8.3 | 8.3 |

| TDS | 500 | 580 |

| Tanins/lignins | ||

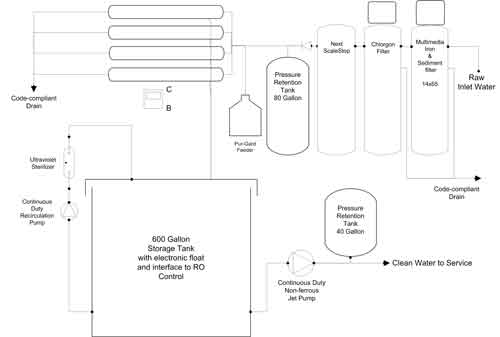

Ultrafiltration case #3

Customer was concerned about trace hardness, suspended solids and potential bacterial contamination on a free-flowing spring.

| Before | After | |

| Hardness | 3 gpg | 0 gpg |

| Iron | 0.5 ppm | 0 ppm |

| pH | 7.0 | 7.8 |

| TDS | 90 ppm | 130 ppm |

| Turbidity | 10 NTU | 0.1 NTU |

Reverse Osmosis case #1

Customer was concerned about high hardness, high sulfates, high conductivity and unpleasant ‘musty’ odors in water. Noise and electrical consumption constraints necessitated the utilization of a quad 4×40 filtration array with low energy/high flux membranes, delivering an aggregate permeate flow rate of 2gpm to the storage tank. High water hardness and bacterial concerns required periodic injection of an acid-based disinfecting cleaning agent. Electronic controls for the reverse osmosis array coordinate intermittent chemical injection as well as periodic membrane flushes to maximize usable service life.

| Before | After | |

| Hardness | 30 gpg | 0 gpg |

| Iron | 1 ppm | 0 ppm |

| pH | 8.7 | 7.5 |

| TDS | 1,500 | 180 |

| Sulfate | 600 ppm | 50 ppm |

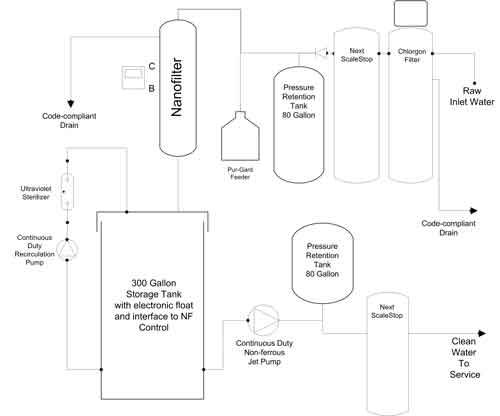

Nanofiltration case #1

Client was concerned about water harness, but didn’t trust scale control technologies and felt that a softener was environmentally unsustainable. This was a municipal (city) water project. A custom NF element was fabricated for an 8” housing to maximize product flow at a delivered pressure of 80psi. Electronic controls for the nanofiltration element coordinate intermittent chemical injection as well as periodic membrane flushes to maximize usable service life.

| Before | After | |

| Hardness | 18 gpg | 1 gpg |

| Iron | 0.1 ppm | 0 ppm |

| pH | 7.9 | 7.6 |

| TDS | 280 ppm | 130 ppm |

Thank you for another great article. Where else could anyone get that kind of information in such a perfect way of writing? I have a presentation next week, and I am on the look for such information.